A Logistics Operator’s Story

Manual coordination between field teams and back office created delays, missing status updates, and escalating follow-ups, until the system was rebuilt by Coaldev to restore visibility and operational control.

TL;DR

In logistics and supply chain operations, field teams, back office, and customers rarely share a single, real-time view of cargo and shipments.

Updates move through emails, calls, WhatsApp, and spreadsheets. Connectivity drops offshore. Information stops flowing. Teams guess, follow-ups multiply, and small issues escalate into customer complaints.

The core problem isn’t people or process. It’s coordination — and the systems meant to support it.

This article breaks down how logistics operators fix coordination by rebuilding IT systems that work in real-world conditions, even with unreliable connectivity. It shows what changed when one operator partnered with Coaldev, and how that shift replaced constant firefighting with predictable, controlled operations.

Below, we unpack what other logistics teams can learn from this change.

Struggling with operational visibility because updates are spread across teams and tools?

Emails and spreadsheets create delays and blind spots offshore.

It is 3 PM, and a customer asks a simple question.

“Where is our cargo?”

The operations team starts searching. Someone checks email threads. Someone calls the field. Someone opens a spreadsheet that may already be outdated.

An offshore operator has the update, but the connection is unstable. The message has not synced yet.

This situation is not rare. It happens every day in marine logistics.

And it is not caused by people doing the wrong work or not working hard enough. It happens because information does not move when and where it is needed.

The real problem is coordination, not effort

Marine logistics does not operate in ideal conditions.

Connectivity drops offshore.

Vessel schedules change.

Ports become congested.

Teams work across time zones and locations.

The real problem is that information is scattered across too many tools.

Most marine logistics operators still rely on:

- Email chains with delayed updates

- Phone calls with no record or audit trail

- Spreadsheets that go out of date quickly

- Standalone systems that do not sync with each other

When updates are spread across tools, no one sees the full picture.Operations teams become reactive instead of staying in control.

Customer teams cannot give clear answers.

Leadership makes decisions based on partial or outdated information.

This is how coordination breaks down.

Seeing similar coordination issues in your operations?

If field updates arrive late or teams work with partial information, it’s usually a sign that system-level visibility is missing.

Why most logistics systems fail?

Many logistics teams operate with one assumption; that connectivity is always available.

In real logistics and transport operations, that assumption does not hold.

When connectivity drops:

- Updates stop syncing

- Teams fall back to manual work

- Information gaps appear

- Delays turn into fire drills

The issue is not digitization itself.

The issue is systems that are not designed for real operating conditions.

Designing systems for real-world marine operations

When one marine logistics operator approached Coaldev, they were facing these exact problems.

- Cargo status updates were manual.

- Information lived in emails and phone calls.

- Customers had limited visibility.

- Offshore teams worked with unstable connectivity.

Coaldev did not start by adding more tools.

Instead, we focused on fixing coordination at the system level.

The guiding principle was simple.

Work must continue even when connectivity is unreliable.

What changes when coordination is fixed

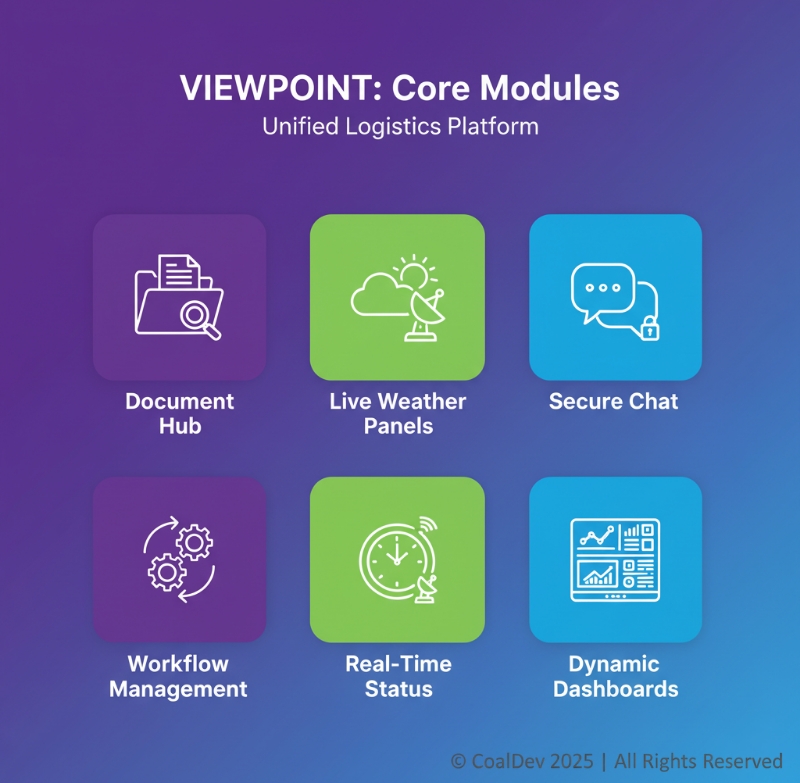

Coaldev helped design a platform that:

- Allows field teams to update cargo status even without connectivity

- Automatically syncs updates when the connection returns

- Gives operations teams one clear view of cargo status

- Removes the need for manual follow-ups

- Keeps customers informed with accurate, timely updates

Instead of chasing information, teams work from a shared source of truth.

When a customer asks, “Where is our cargo?”

The answer is available immediately.

The operational impact

Once coordination is fixed:

- Customer trust improves

- Teams spend less time firefighting

- Decisions are made using current data

- Operations become predictable instead of reactive

This is not about advanced technology for its own sake.

It is about removing friction from everyday operations.

From coordination crisis to operational control

Marine logistics leaders face growing pressure.

Customers expect fast, clear updates.

Delays compound quickly.

Poor visibility damages trust and credibility.

In this environment, coordination is not optional.

It is the foundation of reliable operations.

The question is simple.

Can your systems keep teams aligned when conditions are not ideal?

Reliable cargo visibility for real-world logistics operations

Coaldev builds systems that keep logistics operations coordinated, even offline.