TL;DR

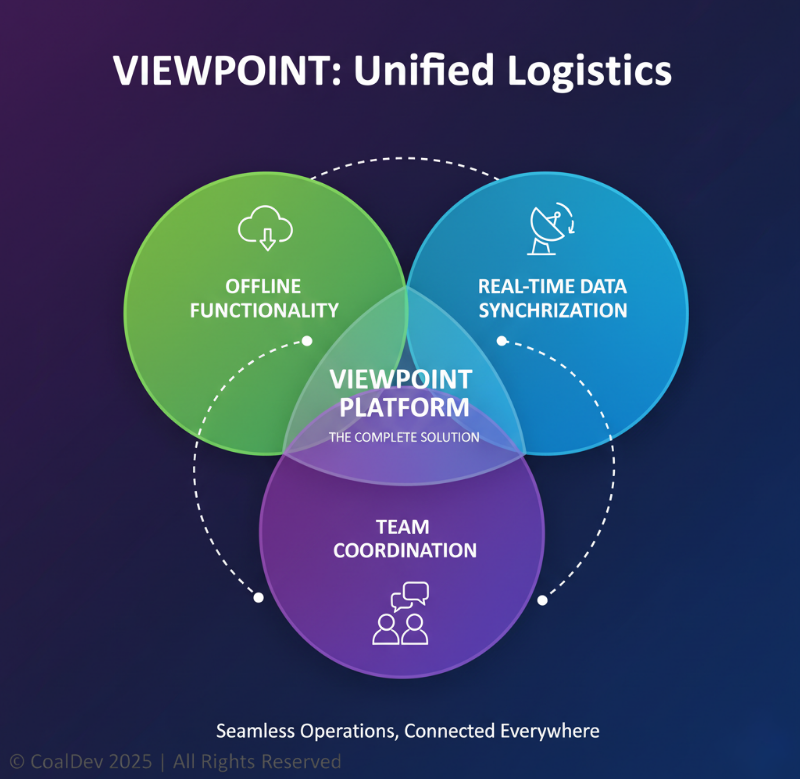

Building software for marine logistics is not about applying standard cloud architectures to a different industry. It is about designing systems that continue to function when connectivity fails, workflows span weeks, and multiple parties depend on the same operational data. Traditional cloud-only approaches break down in offshore environments where updates cannot wait for stable networks.

This article explains how we architected VIEWPOINT as a hybrid, offline-first platform that delivers real-time visibility while gracefully handling disconnections. It walks through the core engineering decisions behind synchronization, event-driven data pipelines, modular services, and security, showing how resilient architecture can eliminate data loss, reduce operational friction, and support complex maritime workflows under real-world conditions.

When STS Marine Solutions approached us to modernize their cargo tracking infrastructure, it was clear the solution had to go beyond typical web application development. Marine operations routinely face network instability, multi-party workflows, and long operational cycles, conditions that quickly break down conventional cloud-only systems. Marine logistics operates in an environment with unreliable connectivity, where data must flow across distributed teams, and operational delays can translate into significant demurrage costs, missed transfer windows, and contractual penalties across marine supply chains. Our engineering decisions needed to prioritize resilience, offline-first capabilities, and seamless synchronization, all while maintaining real-time visibility for stakeholders.

This is how we architected VIEWPOINT, a hybrid cloud platform that transformed fragmented email-and-phone coordination into a unified digital ecosystem that operates reliably in challenging offshore environments.

The Engineering Challenges Behind Marine Cargo Tracking

Before diving into the solution, let’s explore the architectural challenges we faced:

- Connectivity Constraints: Offshore vessels and remote field operators often deal with intermittent or low-bandwidth connectivity. Traditional cloud-only architectures would fail under these conditions because offline periods disrupt data submission workflows, leading to lost updates, incomplete records, and inconsistent operational timelines.

- Asynchronous Workflows: Cargo operations span days or weeks, with customer approvals, offshore loading updates, and surveyor confirmations happening at different times and locations.

- Data Fragmentation: Operational data existed across emails, spreadsheets, and disconnected systems, creating version conflicts and making it difficult to trace the latest cargo status or the responsible party.

- Real-Time Expectations: Despite connectivity challenges, customers and management needed up-to-the-minute visibility into cargo status, ETAs, and operational milestones.

The core engineering challenge was designing a system that felt real-time while gracefully handling offline periods—what we call eventually consistent visibility.

See how this hybrid, offline-first architecture was implemented in a real marine logistics platform.

System Architecture

To solve these real-world constraints, we architected VIEWPOINT as a hybrid online–offline system with three primary layers:

1. Cloud Infrastructure Layer

The foundation is built on cloud-native services optimized for scalability and reliability:

- Application tier: A set of containerized microservices managing business logic, exposed through an API gateway for controlled access.

- Data tier: Relational databases for transactional data, document storage for unstructured content, and time-series databases for operational events.

- Caching layer: A distributed cache to reduce database load and improve response times for frequently accessed data.

- Message queue: An event-driven architecture using message brokers to decouple services and enable asynchronous processing.

2. Synchronization Engine

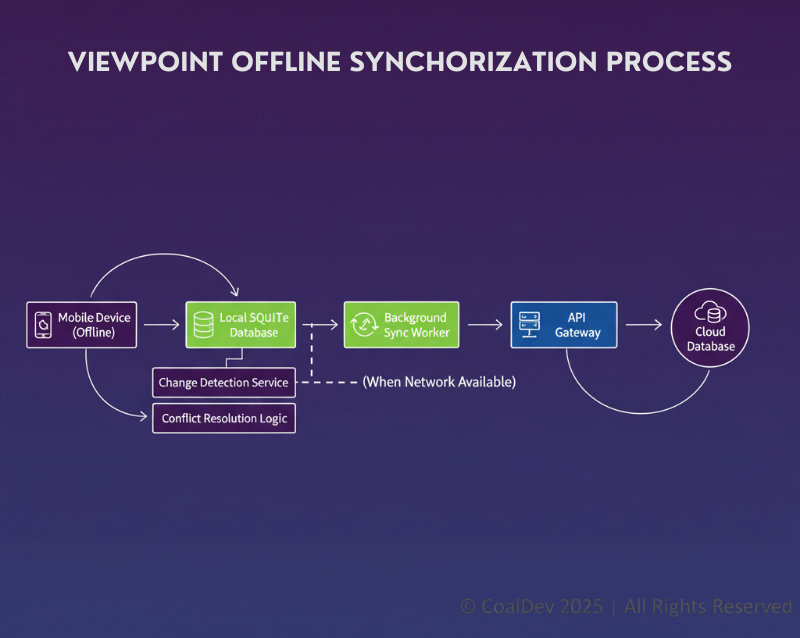

The synchronization engine manages all offline-to-online transitions. Local data is stored in an on-device SQLite database, processed by change-detection and conflict-resolution logic, and automatically synced to the cloud when a network connection becomes available.

These mechanisms ensure that operators can continue working offline without risking data conflicts or duplication:

- Optimistic Locking: Timestamp-based versioning to detect concurrent modifications.

- Conflict Resolution: Last-write-wins for most fields, with manual resolution flags for critical data.

- Delta Synchronization: Only changed records are transmitted, reducing bandwidth usage.

- Retry Logic: Exponential backoff for failed sync attempts with persistent queue management.

3. Real-Time Data Pipeline

For connected users, we built a real-time event-streaming pipeline to ensure that status updates, alerts, and operational events are propagated instantly across teams.

- WebSocket Connections: Persistent bidirectional channels for instant updates.

- Event Sourcing: All state changes are captured as immutable events, enabling audit trails and time-travel debugging.

- Push Notifications: Cross-platform notifications for critical alerts and status updates.

- Dashboard Streaming: Live data feeds to dashboards using server-sent events.

Engineering Decisions That Mattered

Offline-First Mobile Architecture

Rather than treating offline as an edge case, we designed the mobile application to operate fully offline by default, since offshore teams frequently work in locations with intermittent or no bandwidth.

- Complete Cargo Operation Data: Synchronized during connectivity windows.

- Form Validation and Business Logic: Implemented client-side.

- Local Document Storage: With background upload queuing.

- Status Updates: Persisted locally and batch-synced when online.

This approach aligns with best practices for maritime IoT integration, where real-time data from distributed sensors and devices must be captured reliably despite network instability.

Modular Service Design

We decomposed VIEWPOINT into six core modules, each supported by independent microservices:

- Document Management Service: Manages versioning, access control, and storage orchestration.

- Weather Integration Service: Aggregates data from multiple weather APIs with fallback mechanisms.

- Communication Service: Manages threaded conversations with end-to-end encryption.

- Workflow Engine: Orchestrates multi-step processes with state machine logic.

- Event Stream Service: Processes and distributes operational events in real-time.

- Analytics Service: Aggregates data for dashboards and generates reports.

This modularity allows phased rollouts and backward compatibility with legacy systems, which is crucial in maritime environments where upgrades must occur without disrupting ongoing cargo operations.

Addressing Data Quality Challenges

Marine sensors often produce inconsistent readings, such as fluctuating temperature logs or incomplete pressure data, which require automated normalization and anomaly detection before use.

- Input Validation Layers: Schema enforcement at API boundaries with detailed error feedback.

- Data Normalization Pipelines: ETL processes that standardize data formats across different vessel systems.

- Anomaly Detection: Statistical outlier identification for sensor data, with automated flagging.

- Audit Trails: Complete change history for compliance and debugging.

Security and Compliance

Operating across international waters requires robust security:

- Role-Based Access Control (RBAC): Granular permissions tied to organizational roles.

- Data Encryption: AES-256 at rest, TLS 1.3 in transit.

- GDPR Compliance: Data residency controls, right-to-erasure workflows, and consent management.

- Audit Logging: Immutable logs of all data access and modifications.

Results: Engineering Impact

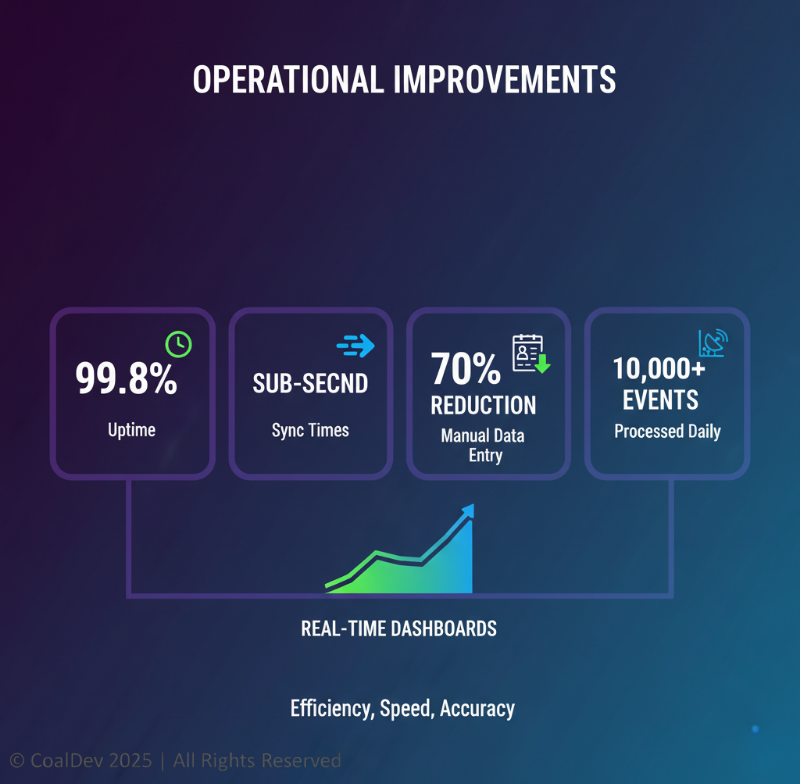

These architectural decisions resulted in measurable operational improvements across field, customer, and management workflows:

- 99.8% Uptime: Across web and mobile platforms.

- Sub-second Sync Times: For most field updates, when connectivity was restored.

- 70% Reduction: In manual data entry through workflow automation.

- Real-Time Dashboards: Processing 10,000+ events daily with <500ms latency.

- Zero Data Loss: During offline periods, with 100% synchronization of queued updates.

Lessons for Building Maritime Systems

Our experience building VIEWPOINT reinforced several engineering principles for designing resilient systems in harsh, distributed environments:

- Design for Eventual Consistency: In distributed systems with unreliable connectivity, embrace eventual consistency instead of striving for real-time everywhere.

- Optimize for Bandwidth: Assume connectivity is expensive and intermittent. Delta synchronization and compression dramatically improve user experience.

- Build Observability Early: Complex synchronization logic requires comprehensive logging and monitoring to debug issues that only surface in production.

- Modular Retrofitting Works: Rather than requiring a complete system replacement, modular designs allow phased integration with legacy systems, reducing risk and cost.

Closing Thoughts

VIEWPOINT demonstrates that with thoughtful architecture, hybrid cloud-offline design, event-driven synchronization, and modular services, we can bring modern digital experiences to traditionally challenging operational environments. The key is recognizing that reliability and resilience are not add-ons; they must be core architectural principles from day one.

For organizations operating in remote, low-connectivity environments, the lessons are clear: offline-first isn’t optional, synchronization logic is mission-critical, and investing in robust data pipelines delivers operational efficiency.

Explore the full case study on architecting a resilient, offline-first cargo tracking system.