TL;DR

Over the years, I have seen that shipping rarely fails because vessels cannot move cargo. It fails when information breaks down. Delays, cost overruns, and customer frustration usually come from disconnected systems, unreliable data, and decisions made without a complete picture.

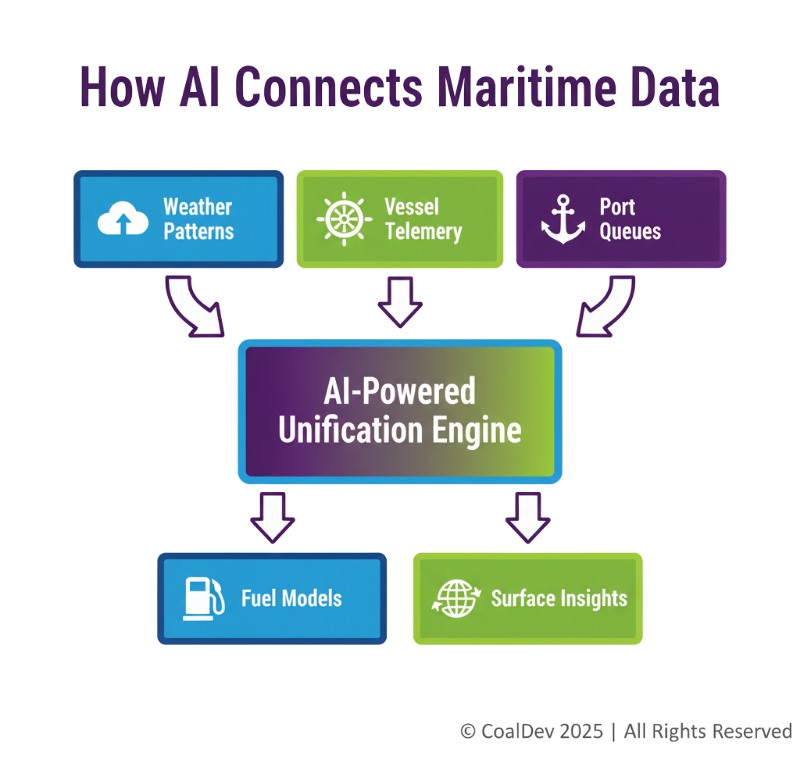

AI is not transforming maritime logistics by replacing people. It is doing so by creating reliable, shared information across vessels, ports, and teams, even when connectivity is limited. When data from weather, vessel telemetry, port queues, and operations is unified into a single system, teams can plan better, respond faster, and operate with confidence. This article explores how AI is already delivering practical value in shipping today and how these principles were applied in a real-world maritime logistics platform built for resilience.

Think of the global shipping industry as the circulatory system of modern commerce. Every day, thousands of vessels move millions of containers across oceans, carrying everything from smartphones to coffee beans. For decades, however, this massive system has relied on surprisingly outdated methods: radio calls, telex messages, and fragmented manual records.

When a cargo ship loses connectivity in the middle of the Pacific or when a port faces congestion, the ripple effects are felt throughout the supply chain. While the challenge in shipping has always been moving goods from point A to point B, the real difficulty has always been the flow of information surrounding these shipments.

Why Shipping Systems Lag Behind Customer Expectations

The marine logistics industry faces numerous environmental challenges that hinder operational efficiency. However, rising customer expectations, driven by real-time services such as food delivery apps, continue to place greater demands on the sector.

Environmental Challenges:

- Harsh salt air that corrodes equipment.

- Connectivity issues, especially miles offshore.

- Sudden weather changes that complicate planning.

Customer Expectations:

- Real-time tracking similar to food delivery apps.

- Seamless communication from start to finish.

AI as the Connective Tissue

This is where artificial intelligence comes in, not as a flashy replacement for human judgment, but as the glue that holds complex systems together.

AI is revolutionizing maritime logistics by processing large volumes of previously unavailable operational data. This data-driven approach enables more efficient decision-making and reduces delays.

Key Operational Data AI Processes:

- Weather Patterns: AI predicts weather conditions to help plan better routes.

- Vessel Telemetry: Monitors vessel status in real-time to optimize performance.

- Port Queues: AI analyzes port traffic to optimize docking and reduce wait times.

- Fuel Models: AI forecasts fuel consumption to reduce costs and improve efficiency.

- Surface Insights: Uses satellite data and real-time information to enhance navigation.

Example of AI Impact:

- AI-Powered Routing Tools: AI can flag incoming storms hours earlier than traditional systems, enabling planners to adjust course in time and prevent cascading delays across the supply chain.

- Predictive Maintenance: AI systems analyze sensor data from ship engines to predict potential failures before they happen, reducing downtime by 20-30% and saving millions annually.

- Port Congestion Management: AI-enabled platforms monitor port queues and traffic in real-time, optimizing vessel docking times and reducing wait times, ultimately improving the efficiency of the entire port operation.

- Fuel Efficiency Optimization: AI models analyze fuel consumption patterns and suggest optimal routes, reducing fuel costs while improving environmental compliance through more intelligent decision-making

Predictive maintenance is another key breakthrough. Machine learning algorithms process sensor data from ship engines and other critical systems to predict potential failures weeks in advance. This reduces downtime by 20-30% and saves millions annually. It’s like having a mechanic who contacts you weeks before your car breaks down.

Fleet management tools can now simulate emissions and vessel schedules simultaneously, balancing service commitments with environmental compliance. Autonomous vessels, such as the Yara Birkeland, are already operating with zero emissions. These are no longer experiments; they’re operational realities reshaping global commerce.

Perhaps AI’s most valuable contribution is its ability to create a shared source of truth. Modern logistics platforms now consolidate vessel telemetry, port wait times, weather forecasts, and booking schedules into a single, AI-driven data layer accessible to offshore crews, field operators, customers, and executives. Companies such as Poloplast have already demonstrated this in practice by migrating to unified AI-powered supply chain systems that integrate data from multiple operational tools into a single, validated dashboard, improving planning accuracy and ensuring all teams work from the same real-time information.

See how we applied these principles in a real maritime logistics platform.

Industry research further shows that AI-enabled visibility platforms enable organisations to detect port congestion, supplier delays, and weather-driven risks in real time, ensuring all stakeholders see the same update and can coordinate decisions without manual reconciliation. Rather than replacing human expertise, AI strengthens it by eliminating information friction and ensuring everyone operates from the same factual baseline.

Making It Real: A Logistics Transformation Story

Coaldev’s partnership with STS Marine Solutions aimed to modernise cargo tracking and communication systems without disrupting day-to-day operations. This challenge wasn’t just about upgrading technology but also about overcoming significant logistical, cultural, and connectivity hurdles typical of the industry.

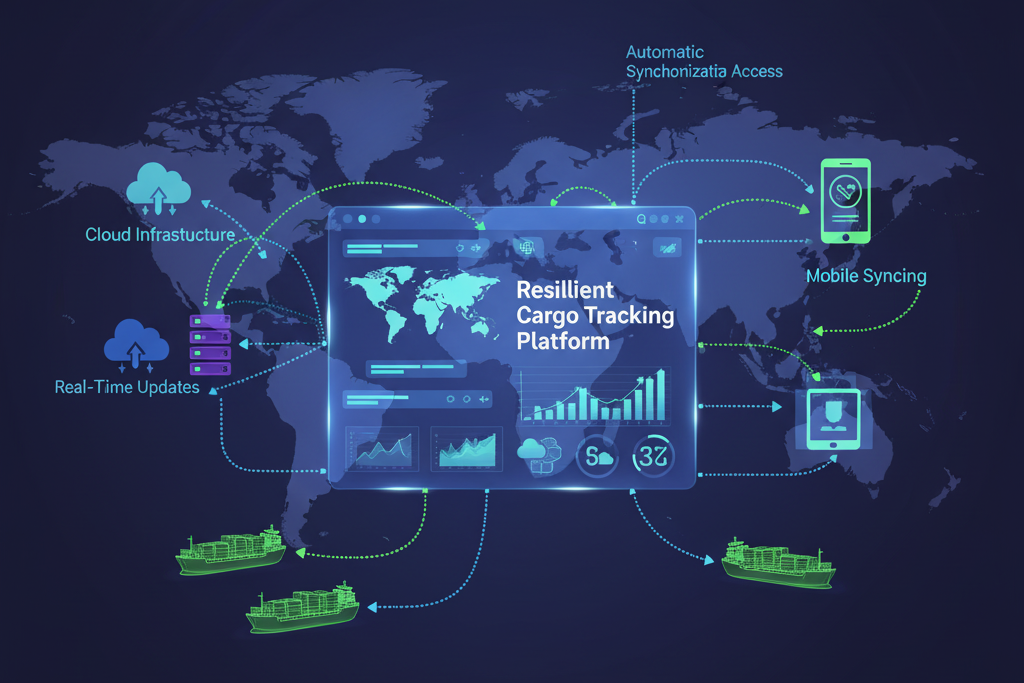

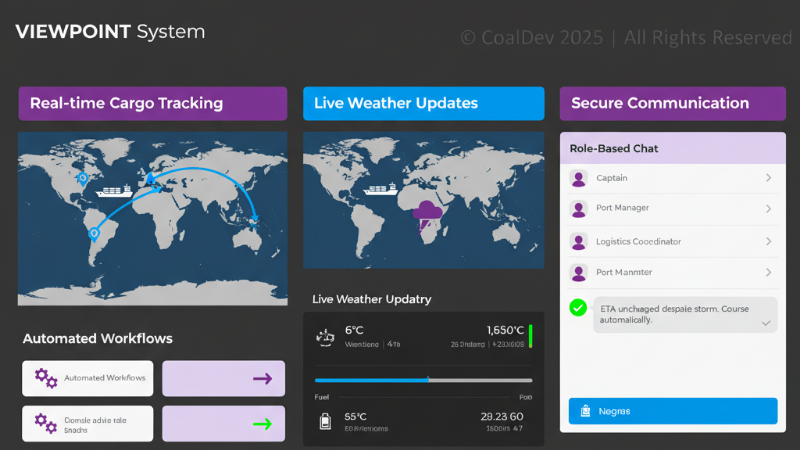

VIEWPOINT was Coaldev’s solution: a cloud-based portal built on a single core principle: the system must remain functional without a network connection.

Key Features of VIEWPOINT:

- Hybrid Architecture: Combining real-time dashboards with offline data storage and automatic synchronization.

- Offline Functionality: Enabling field operators to update cargo data even when disconnected from the network, with automatic syncing once back online.

- Unified System: VIEWPOINT integrated multiple functions to ensure seamless information flow.

Specific Functions Unifying VIEWPOINT:

- Document Management: Version control and easy access to the latest documents.

- Live Weather Updates: Real-time updates to support operational decision-making.

- Secure Role-Based Chat: Ensuring secure communication within teams.

- Workflow Automation: From RFQs to invoicing, automating key steps in the process.

- Real-Time Status Tracking: Continuous updates on cargo status for stakeholders.

- Dynamic Executive Dashboards: High-level insights for real-time decision-making.

The integration of these features created a unified ecosystem in which information flowed seamlessly across teams and locations.

Operational Benefits:

- Faster Processing: Automated approvals sped up operations.

- Improved Visibility: Real-time tracking boosted customer confidence.

- Accelerated Decision-Making: Built-in communication tools allowed quicker decisions.

The most significant benefit was operational resilience. Coaldev could now coordinate complex workflows across disconnected environments while maintaining data integrity and ensuring compliance.

The Next Wave

The maritime industry is entering a new era of digital transformation, with AI, automation, and analytics driving a revolution in how operations are managed and executed.

AI-driven systems are no longer confined to research labs; they are now reshaping port operations, vessel routing, and maintenance schedules, enabling real-time decision-making and significantly reducing inefficiencies.

- Key Points Driving the Next Wave:

- AI Systems: Autonomous systems are increasingly making real-time decisions, such as scheduling maintenance and adjusting operations based on live data.

- Data Standardization: The push for unified, real-time data across operations ensures that stakeholders have consistent, actionable insights.

- Cybersecurity: As AI becomes more integrated into maritime logistics, robust cybersecurity measures are essential to protect sensitive operational data.

- The Future Focus:

- AI’s True Value: The future of AI in shipping isn’t about replacing human expertise. It’s about creating digital environments where human expertise can work at peak effectiveness.

- Creating Reliable Systems: AI’s real value lies in building synchronized, reliable systems that function even under challenging conditions.

- Simplifying Complex Operations: By transforming opaque manual processes into transparent, auditable digital workflows, AI platforms simplify and streamline maritime operations

While the ships themselves may not have changed dramatically, the systems connecting them to the world have been quietly rebuilt from the ground up, creating a transformative shift in the way maritime logistics operates.

Explore the full case study on building an offline-first maritime logistics platform.